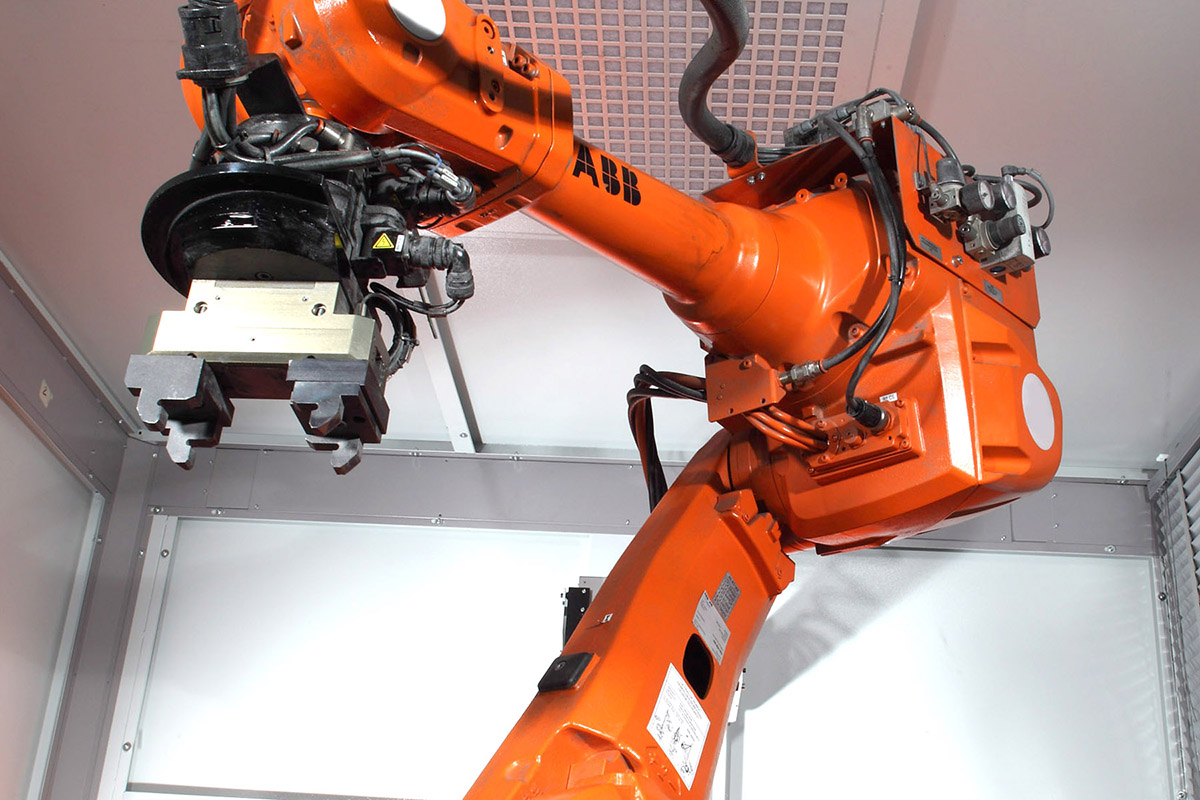

The highlight of company equipment is definitely the ALVIN ROBOT.

Conceived by the company owners, this robot is able to carry out continuous cycle maximum precision processes, guaranteeing fast and punctual deliveries. This was an important investment for the company economically, but a great step forward in productivity, precision and reduced lead times.

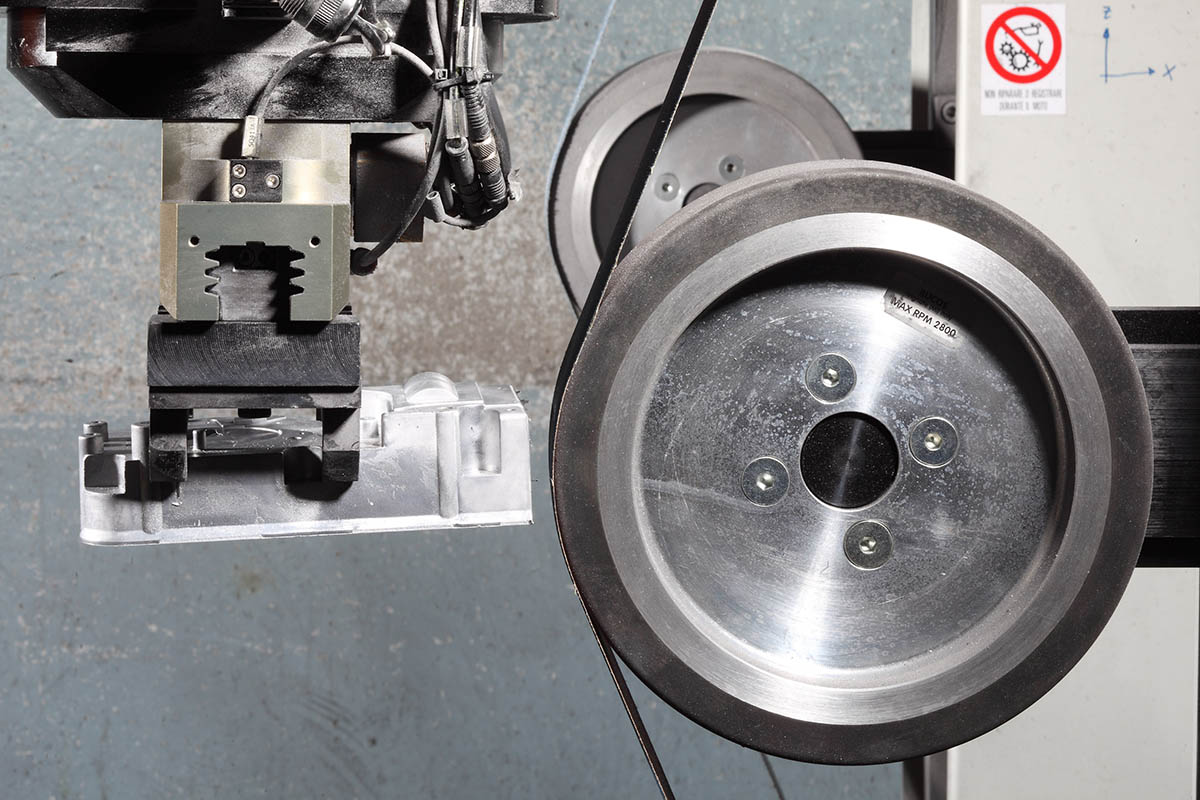

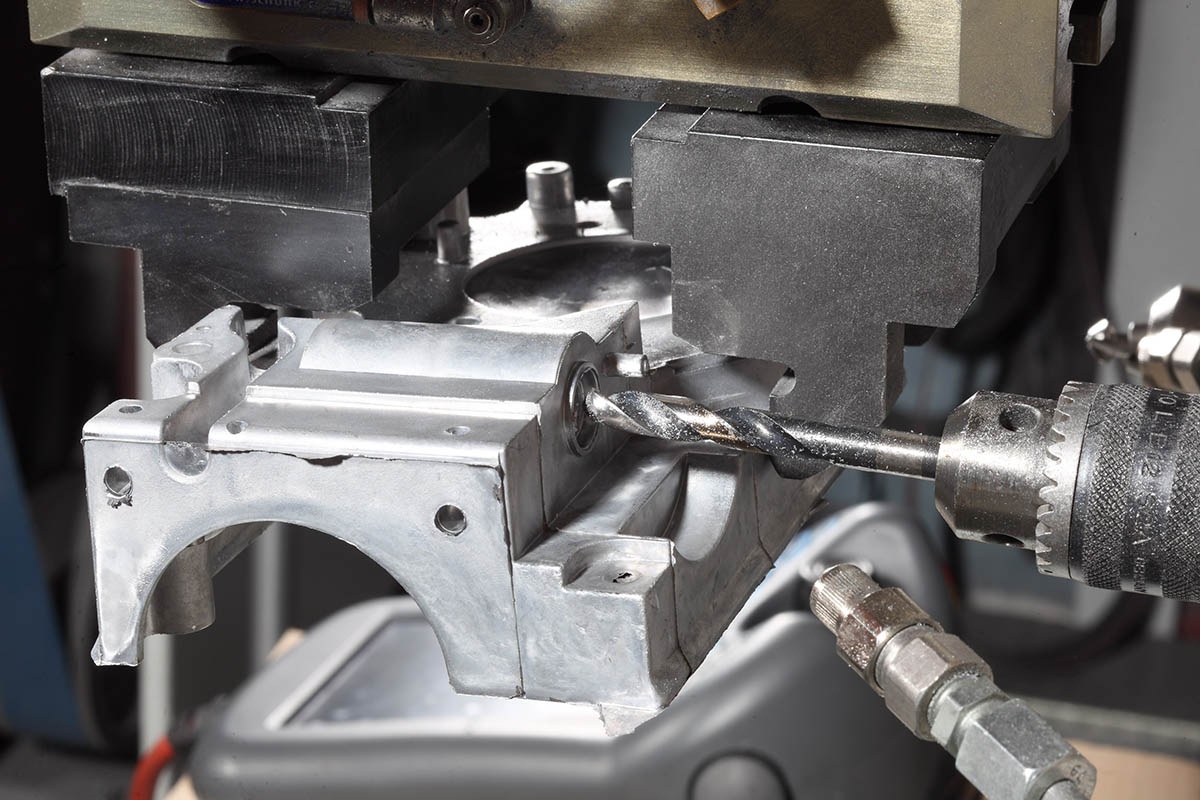

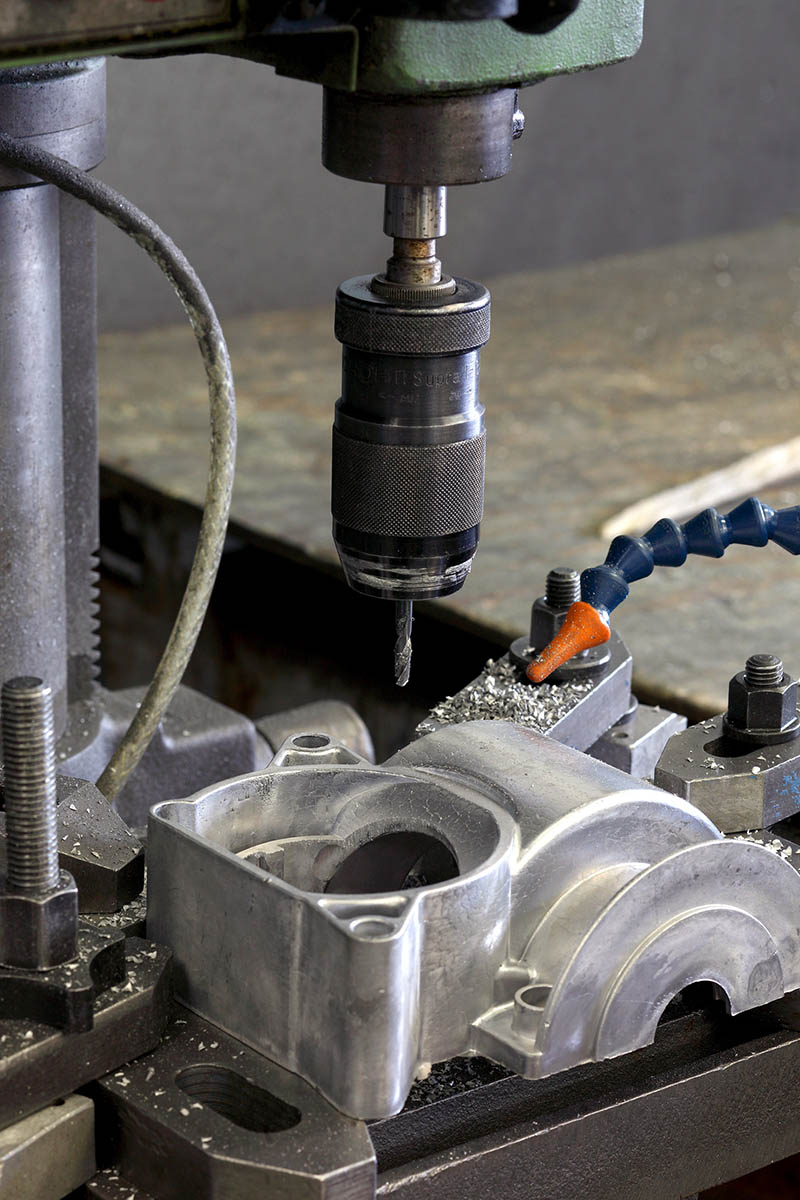

After loading Alvin with a number of parts, which varies according to their size, it is able to autonomously analyse the position of each single part by means of its camera, and then begins the finishing operations. A range of different programs and tools can be set, to enable Alvin to carry out all the different processes.

Alvin can provide drilling, filing, fettling finishes and other minor mechanical works, such as milling.